Conversion Cost per Unit

Utilization Growth %

ROI / Value Creation per Unit Time per Unit Area

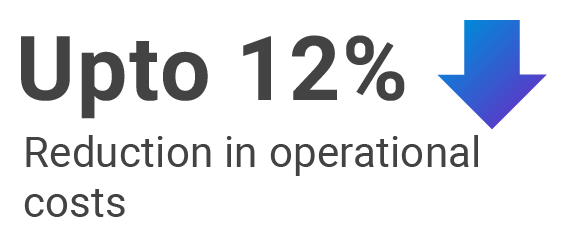

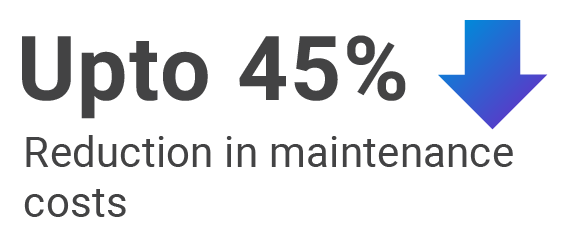

Cost of Maintenance per Unit

Safety & Risk Management

ROI / Production Agility

Digital Tool Scatter / Integration Complexity

AI-driven Site-wise Dashboards + Schedules

ROI-centric Digital Transformation

Output Growth %

% Decisions Based on AI Prescriptions

Cost Competitiveness

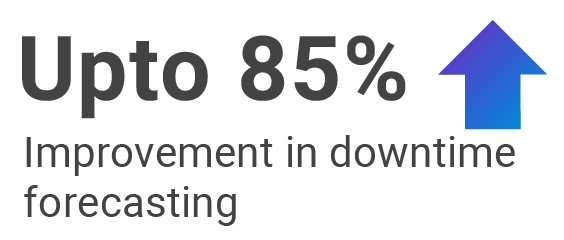

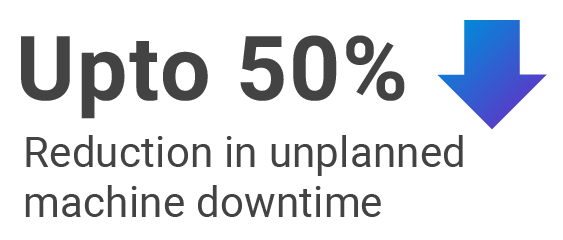

Unscheduled Downtime

% AI Prescriptions Accepted & Acted Upon

Asset Reliability

Cost of Energy per Unit

Energy Efficiency

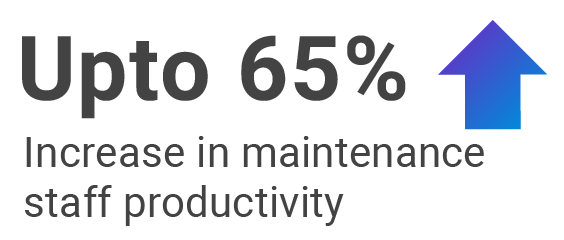

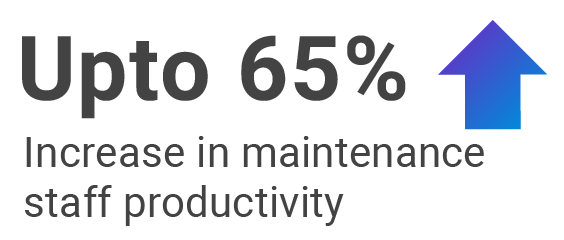

Productivity Growth %

Digital Ways of Working

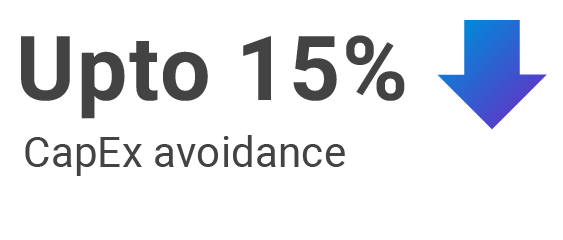

Digital Transformation ROI

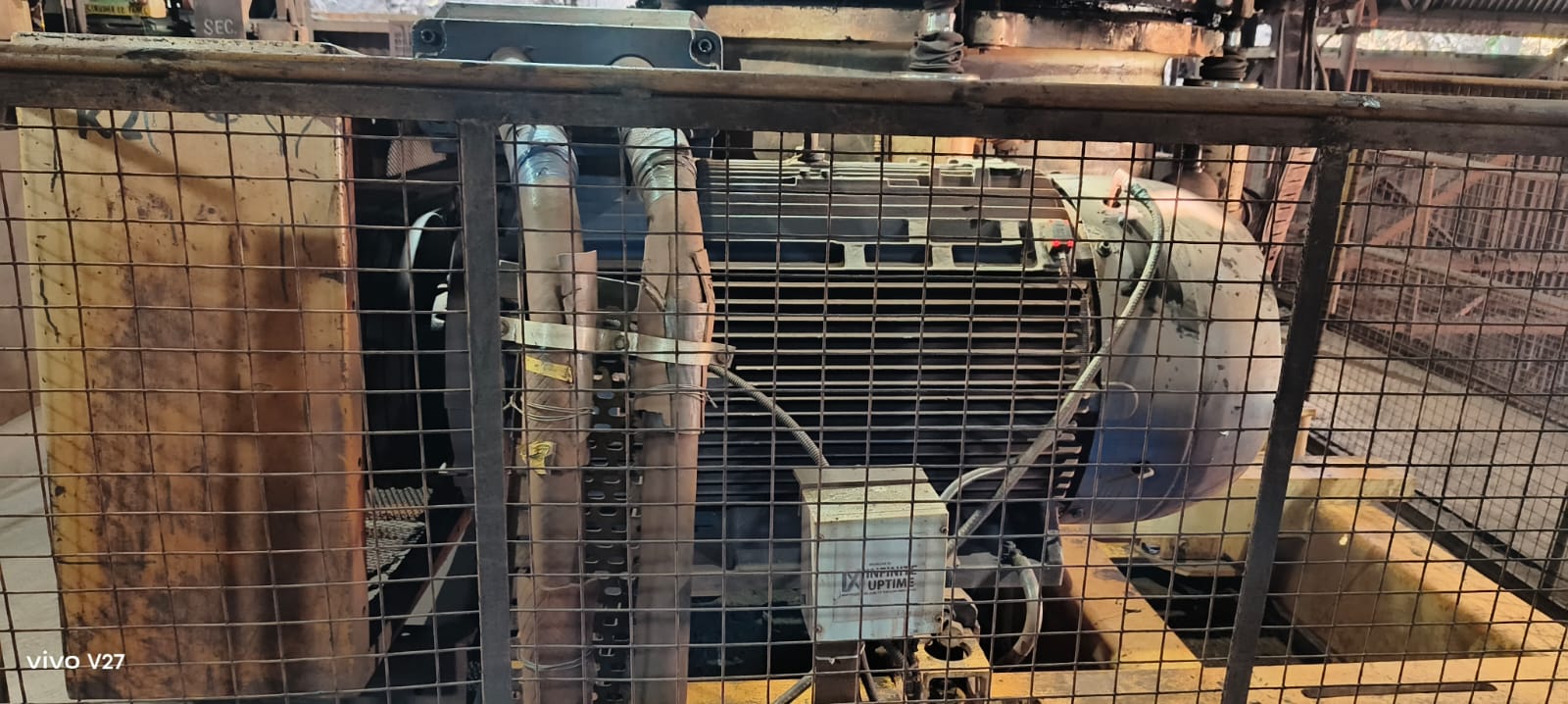

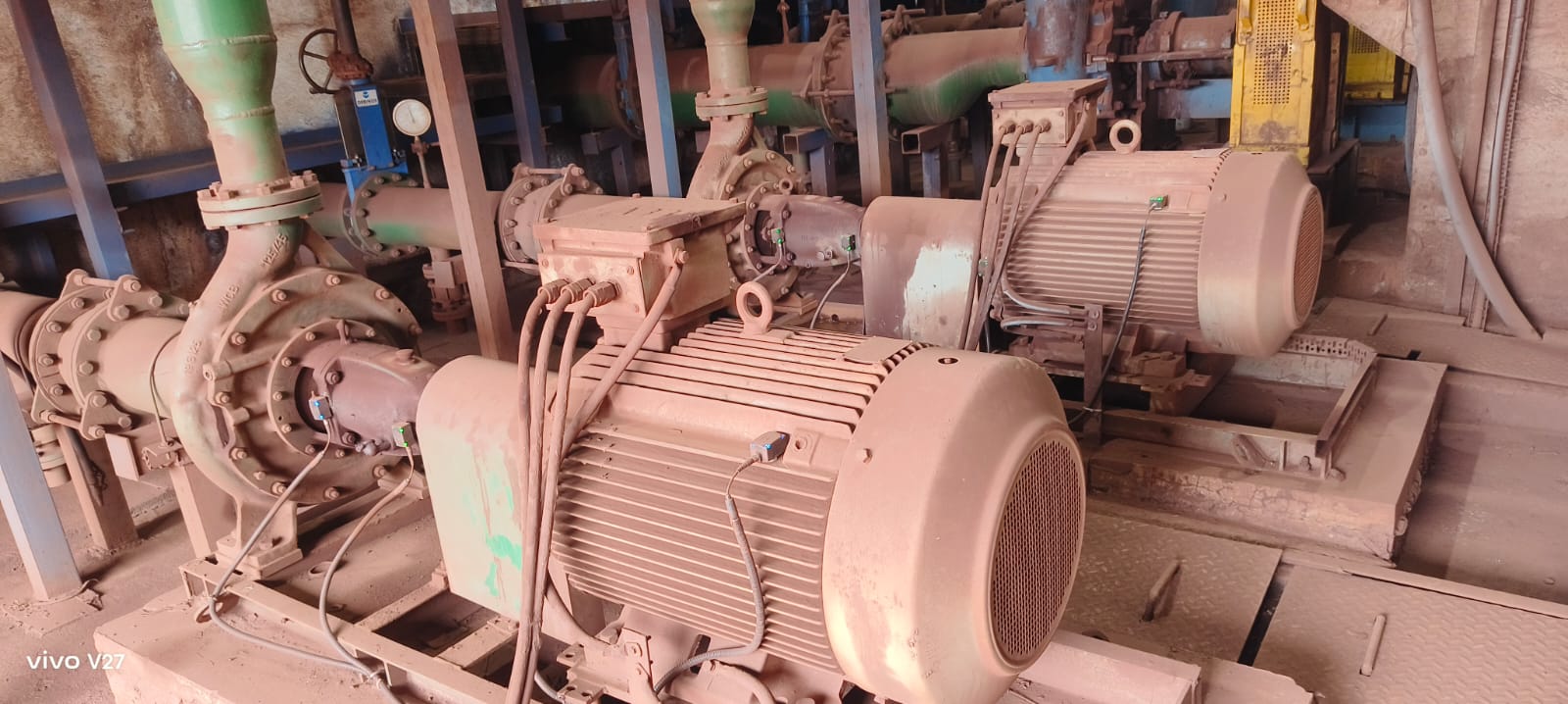

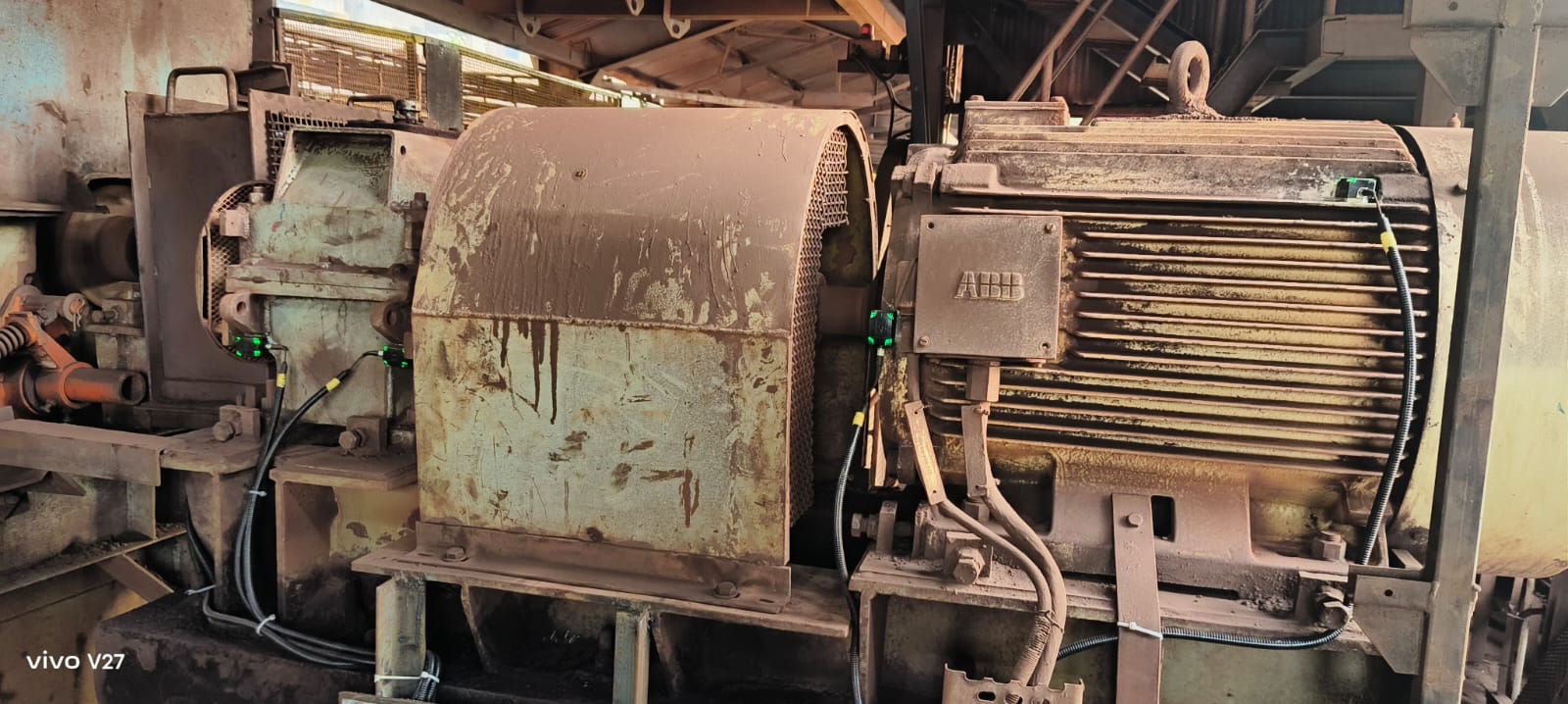

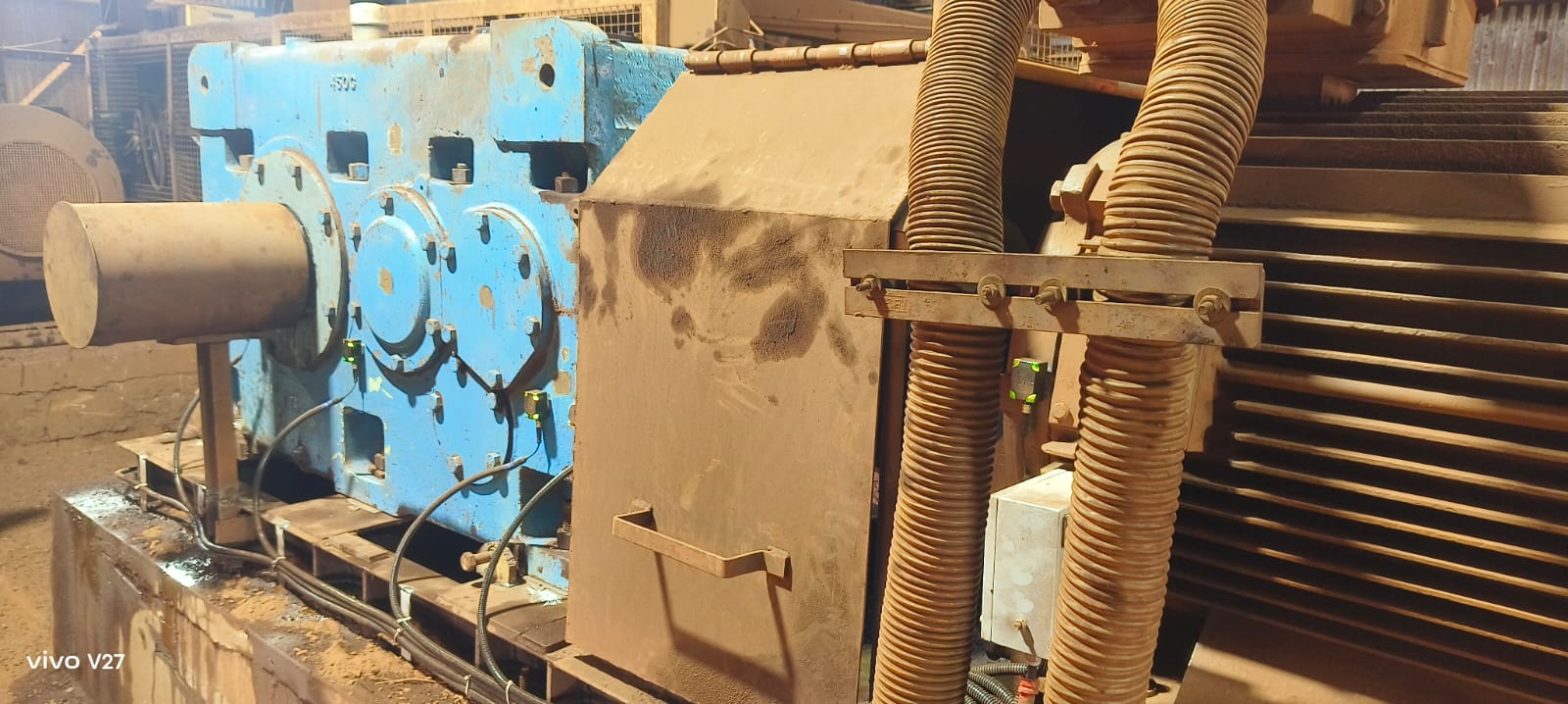

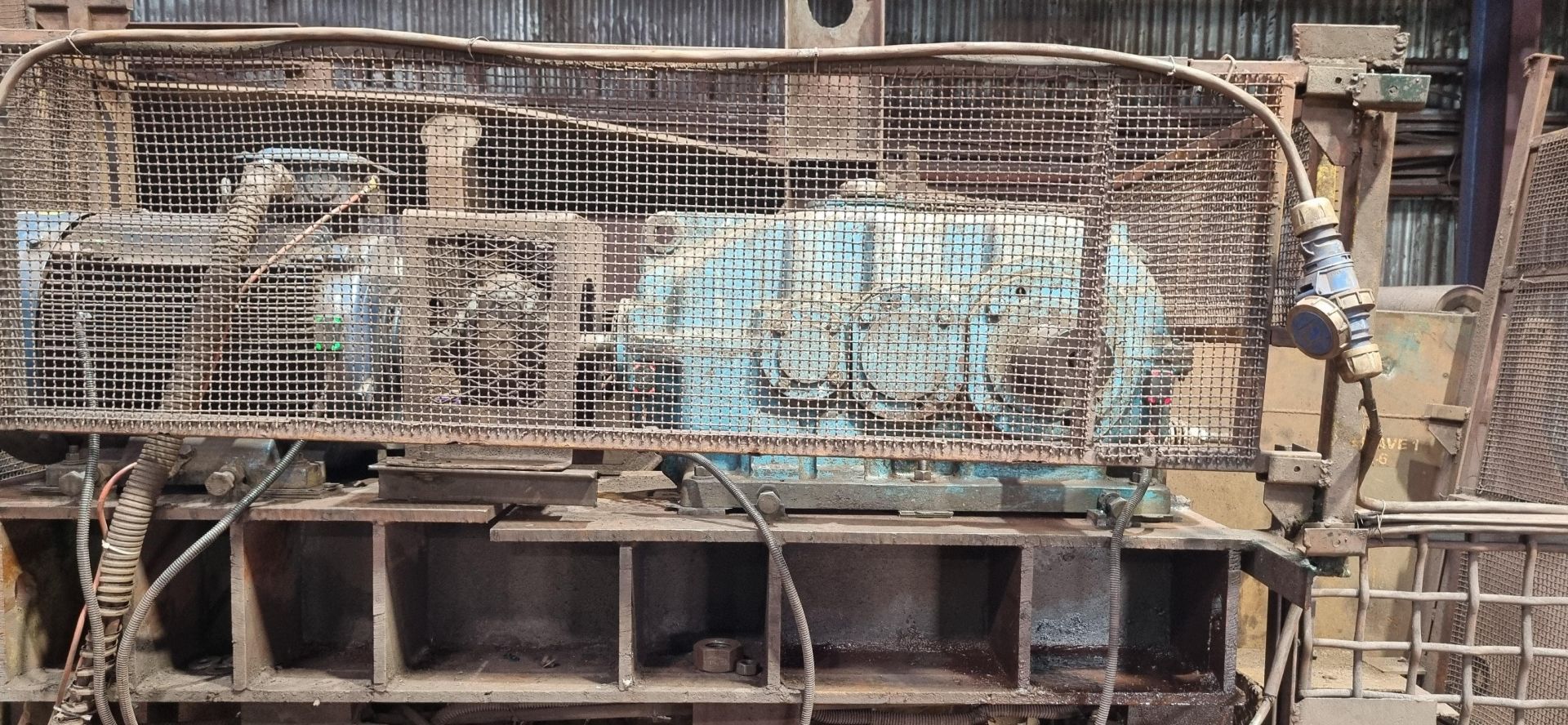

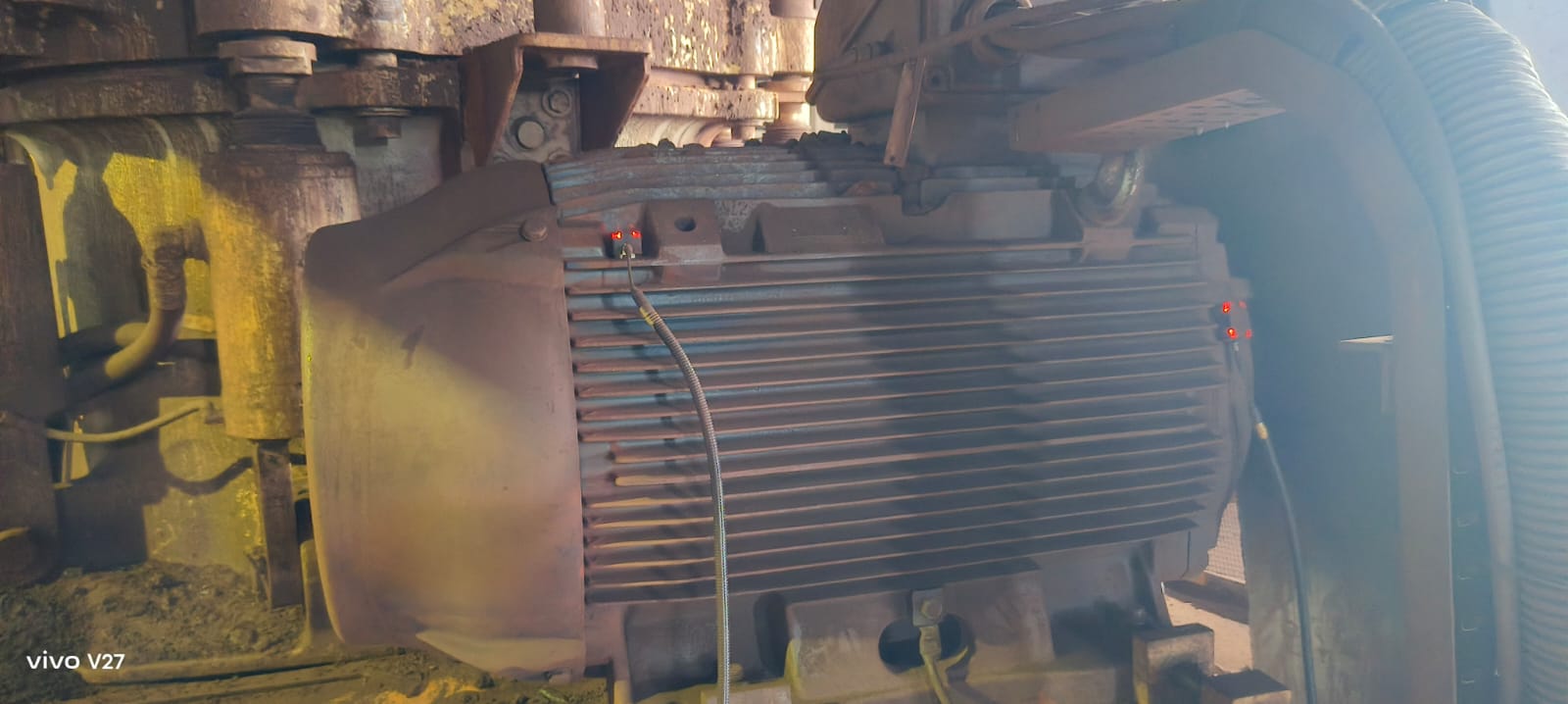

Critical Equipment

Critical Equipment

Critical Equipment

Critical Equipment

Critical Equipment

| KPI | Before PlantOS | Post-CoE Action | Tangible Impact |

|---|---|---|---|

| Energy Consumption per Ton | High & inconsistent due to idle runs and non-optimized load | Equipment-level energy mapping & operation- time correlation |  8–15% reduction in

energy cost 8–15% reduction in

energy cost |

| Mean Time Between Failures (MTBF) | Frequent unplanned breakdowns, low reliability | Predictive maintenance insights, condition monitoring |  MTBF improved by

20–30% MTBF improved by

20–30% |

| Equipment Availability | Unknown idle periods, poor utilization | Real-time run/idle/failure tracking with alerts |  10–25% boost in

availability 10–25% boost in

availability |

| Production Cost per Ton | Fragmented visibility across departments | Integrated energy + maintenance + quality data per batch |  Cost rationalization

through holistic

insights Cost rationalization

through holistic

insights |

| Process Quality Analysis | Reactive issue detection after poor recovery or rejects | Live trend monitoring of process parameters |  Consistency in

quality, 5–10% defect

reduction Consistency in

quality, 5–10% defect

reduction |

| Operational Visibility | Manual data logging, siloed systems | Unified, real-time dashboards for all KPIs |  Faster decisions,

centralized insights Faster decisions,

centralized insights |

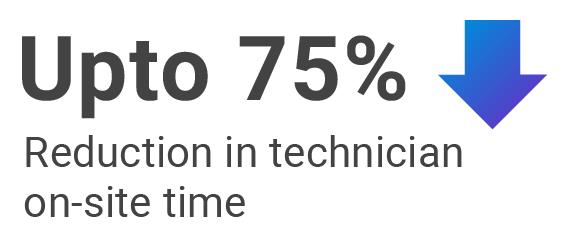

| Maintenance Response Time (MTTR) | Long delays due to reactive maintenance | Downtime reason analysis + auto-alert workflows |  MTTR reduced by

20–30% MTTR reduced by

20–30% |

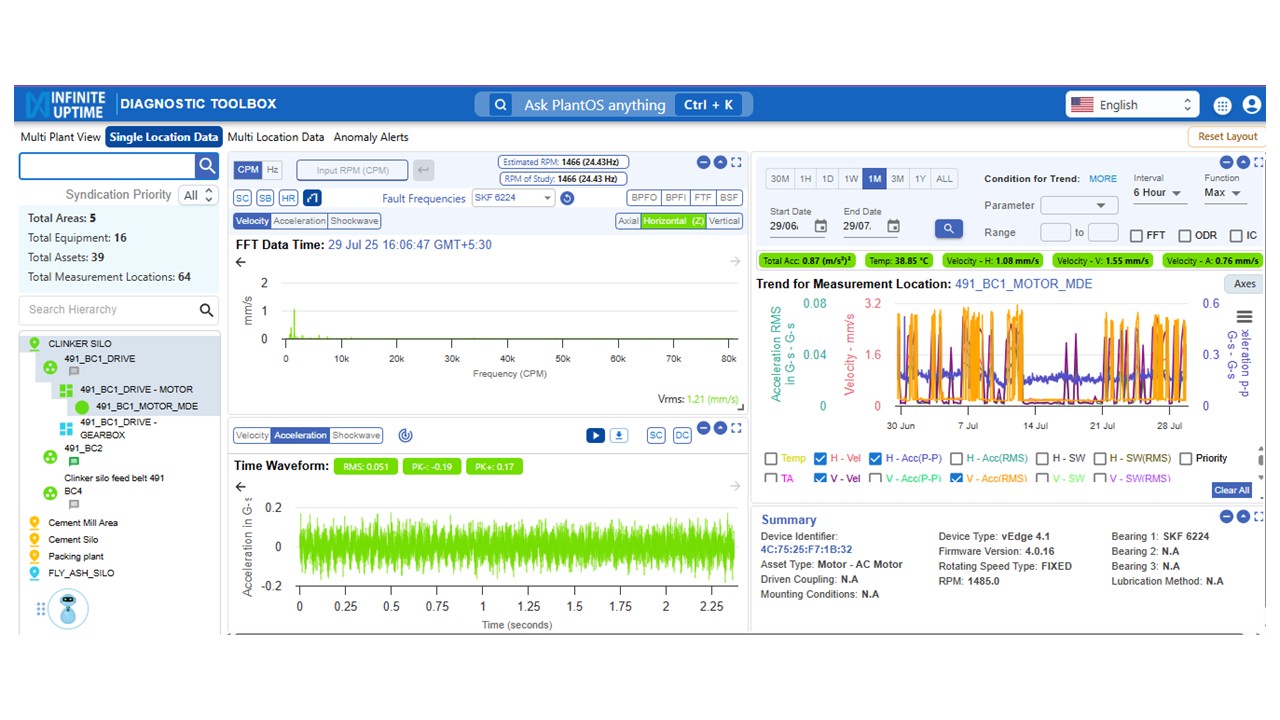

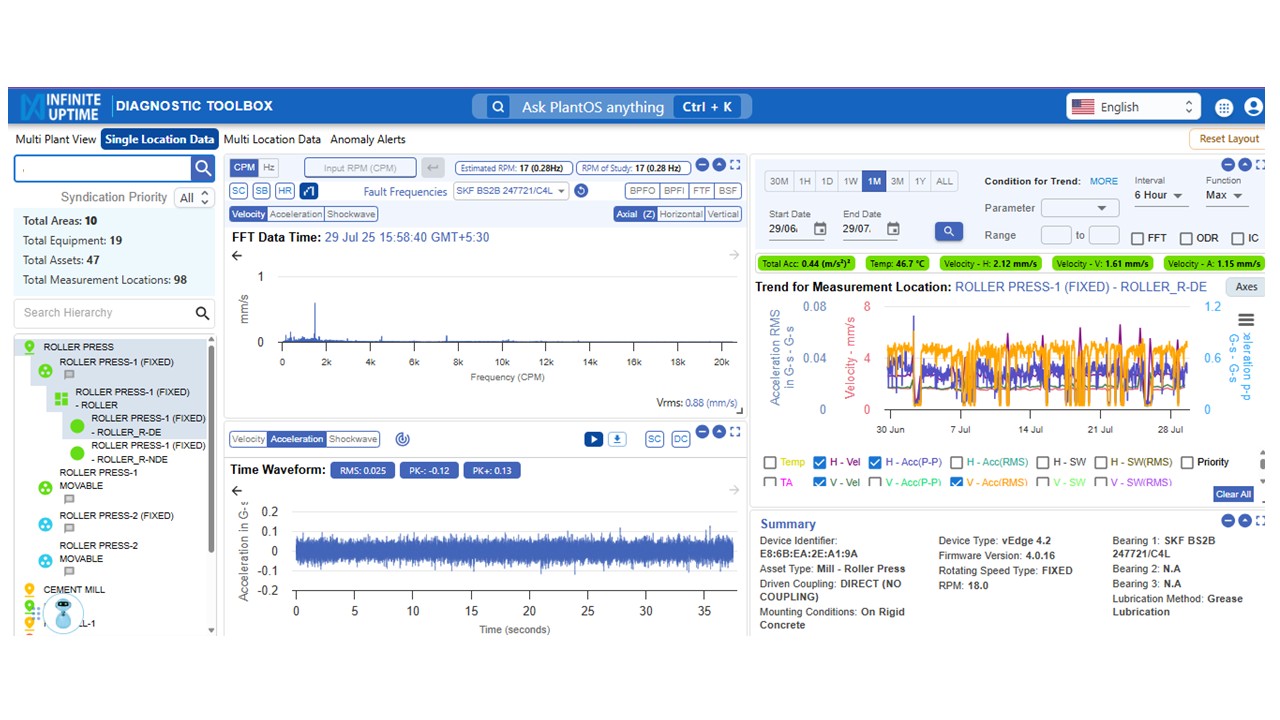

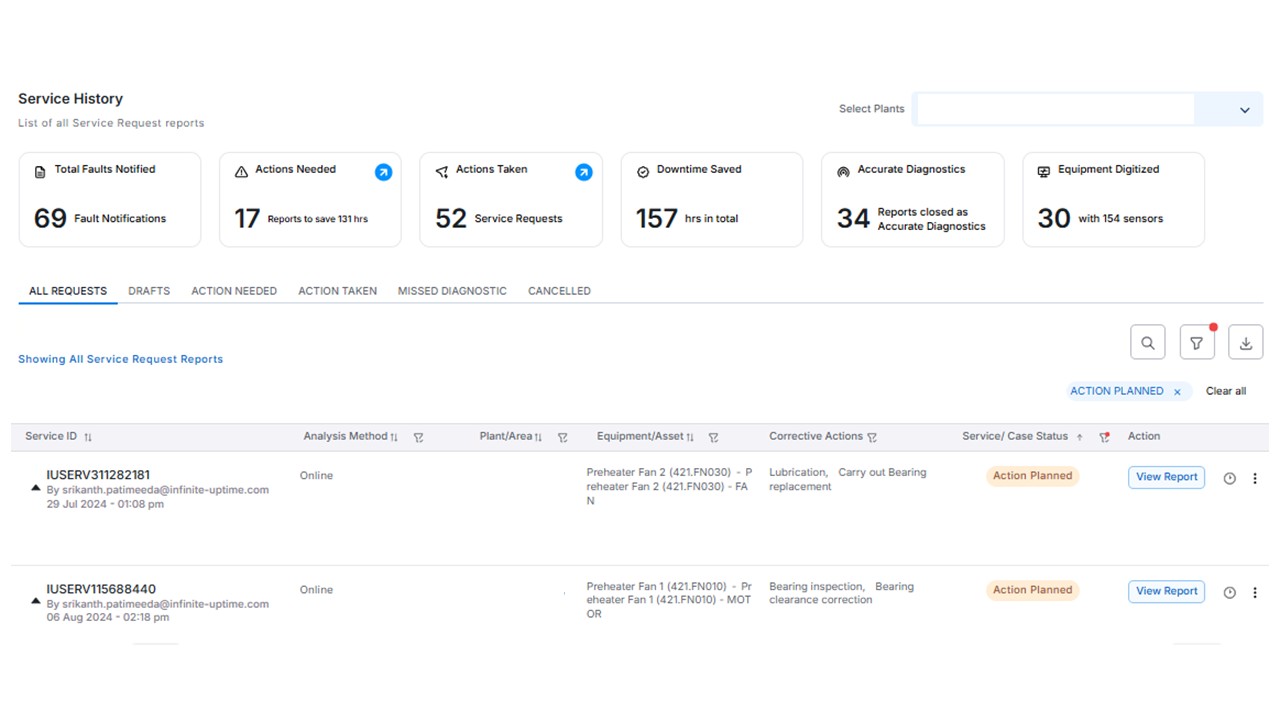

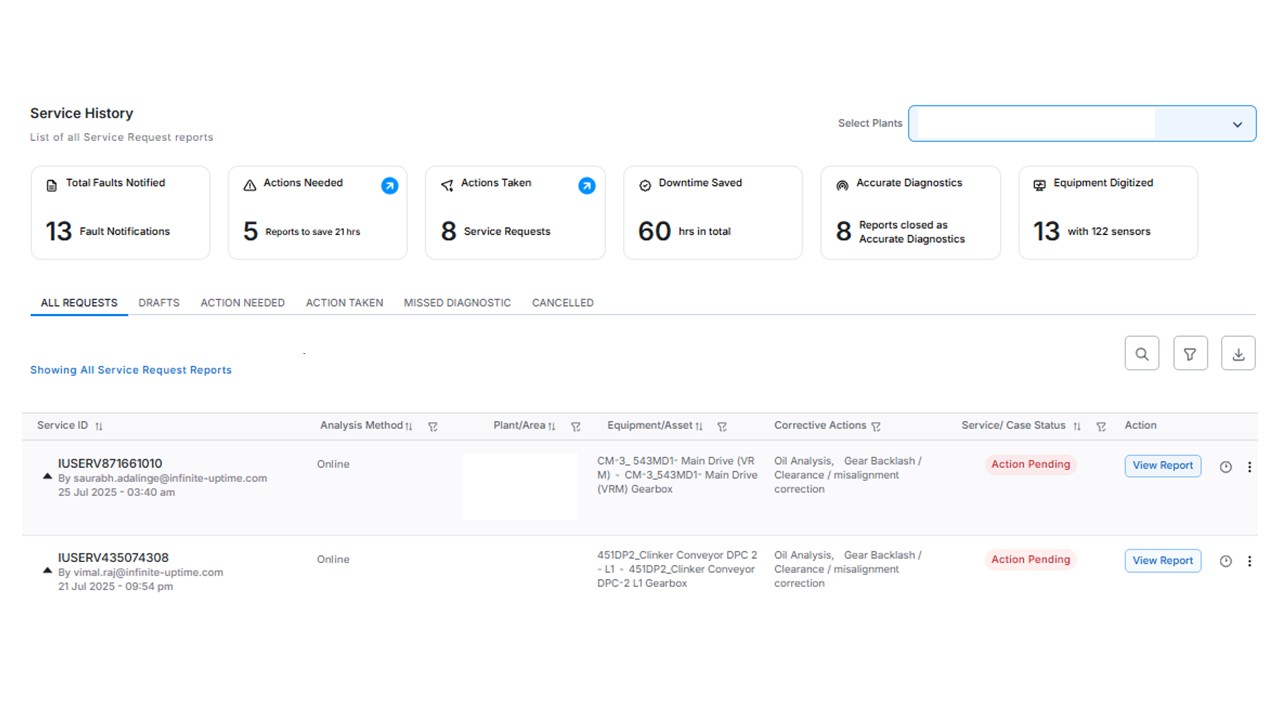

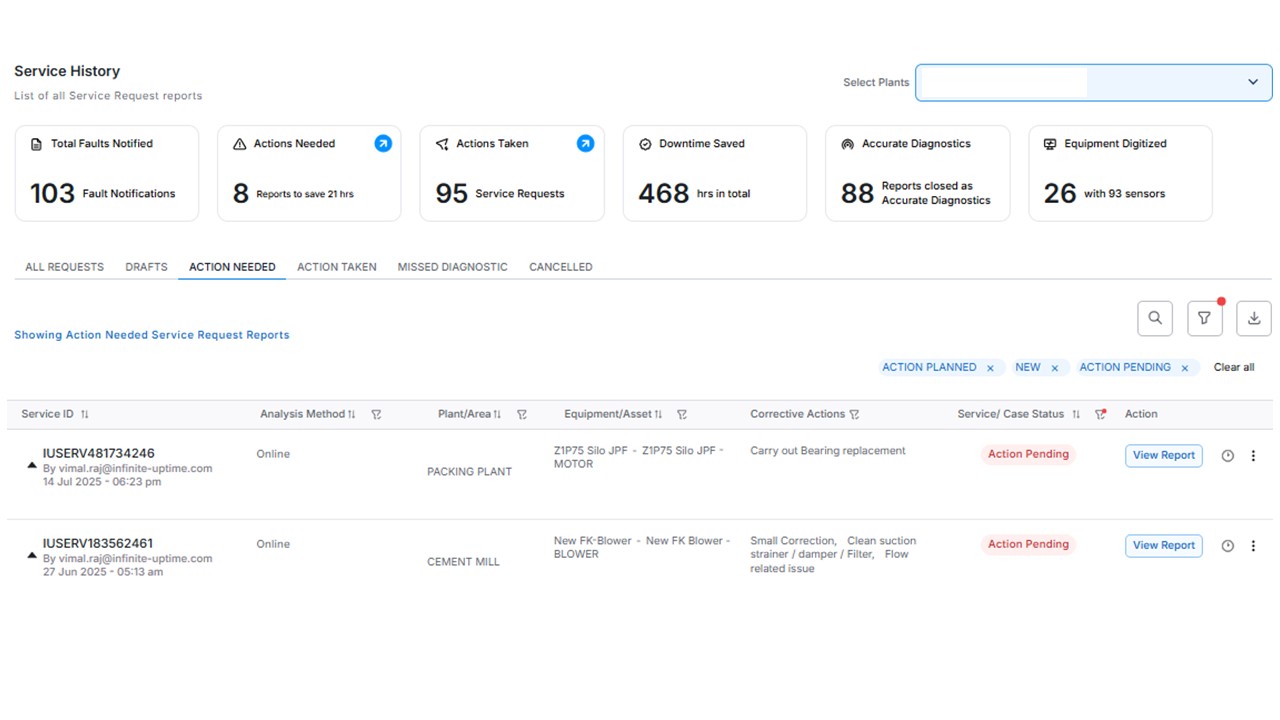

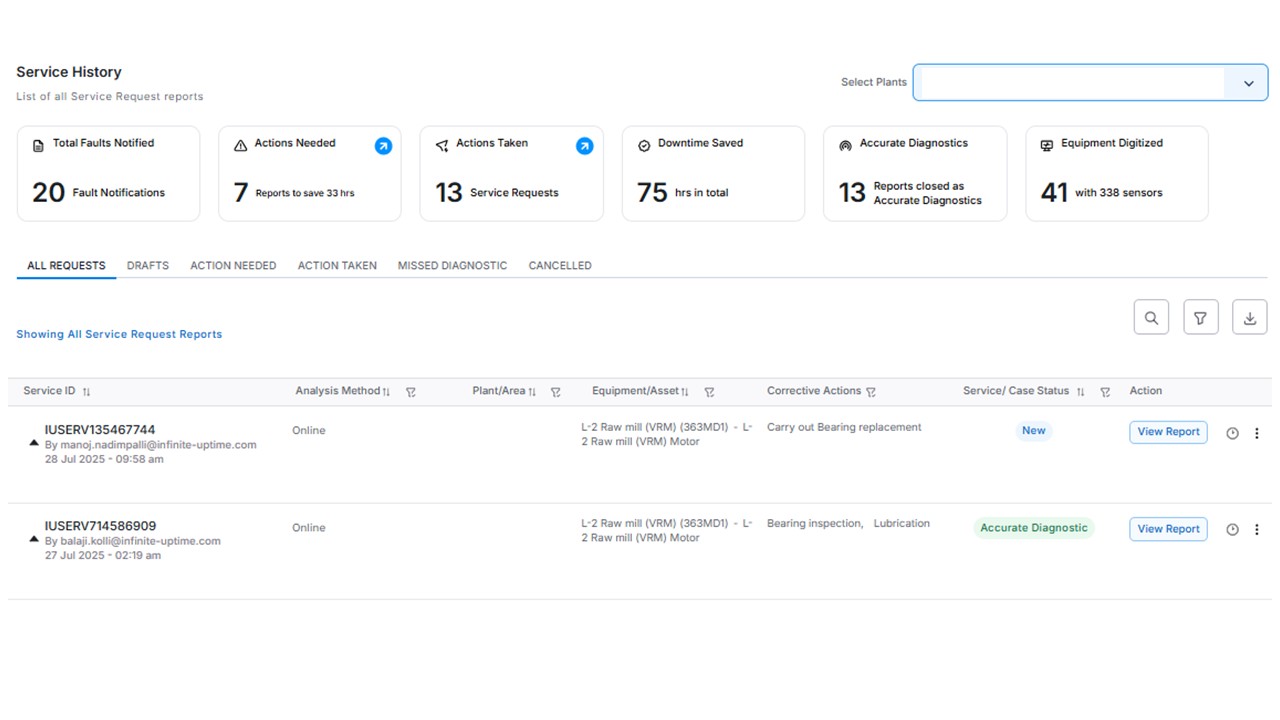

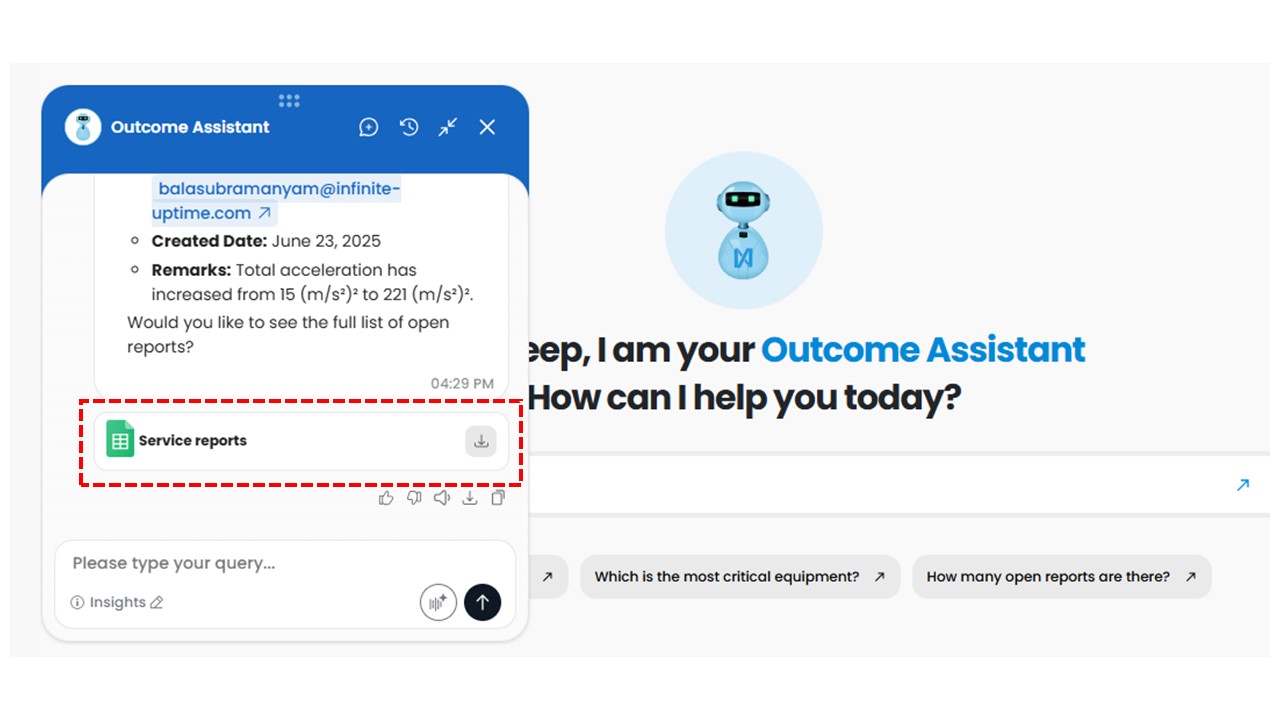

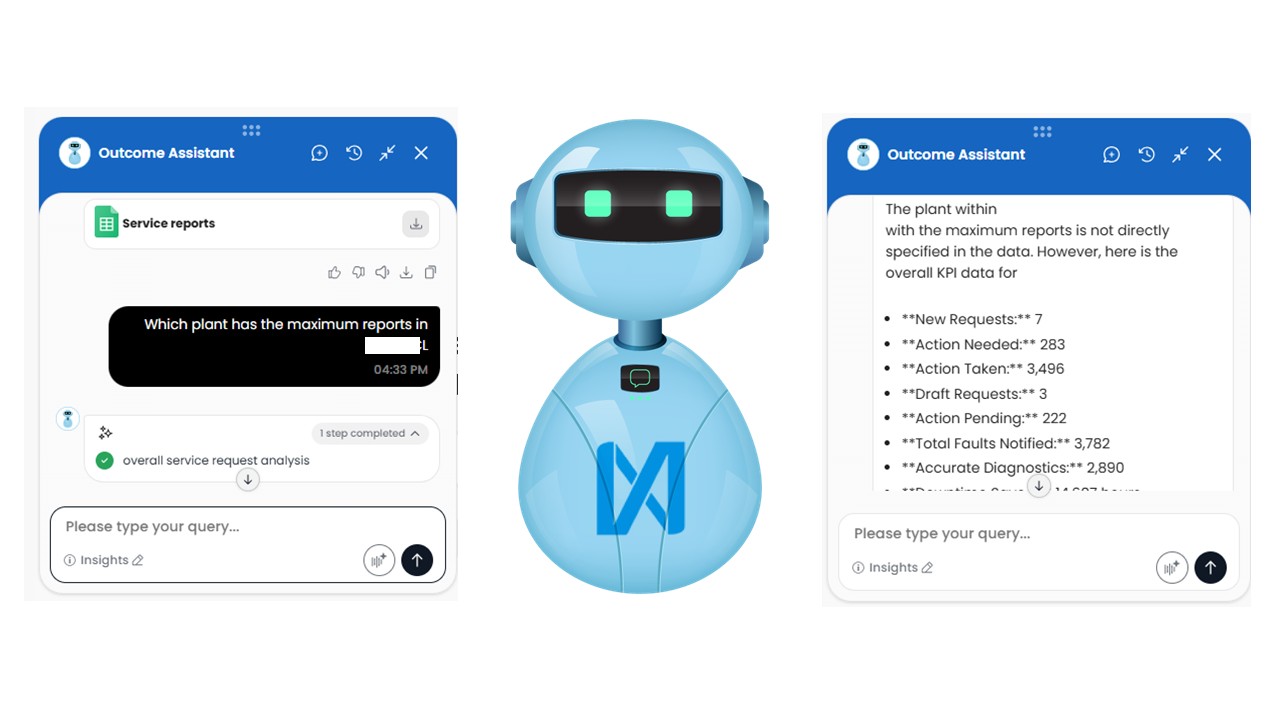

Prescriptive Maintenance

Prescriptive Maintenance Energy Efficiency

Energy Efficiency